Stainless steels along with nickel based alloys are often selected for many applications in corrosive environments. While resistance to corrosion makes them a favourable choice, poor tribological behaviour may prevent…

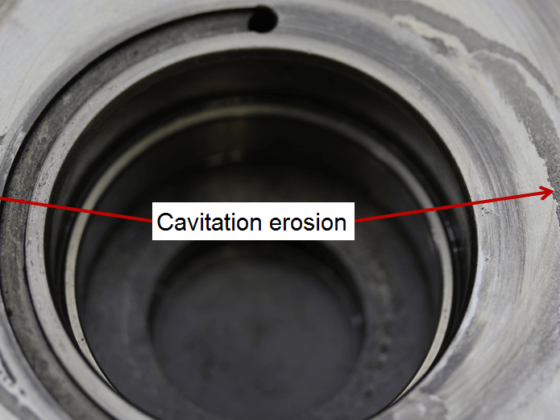

read moreWhat is cavitation erosion? Cavitation erosion is an effect of surface deterioration and surface material loss, mostly in hydraulic machinery and the associated components. Pressure differences in high-velocity liquids can…

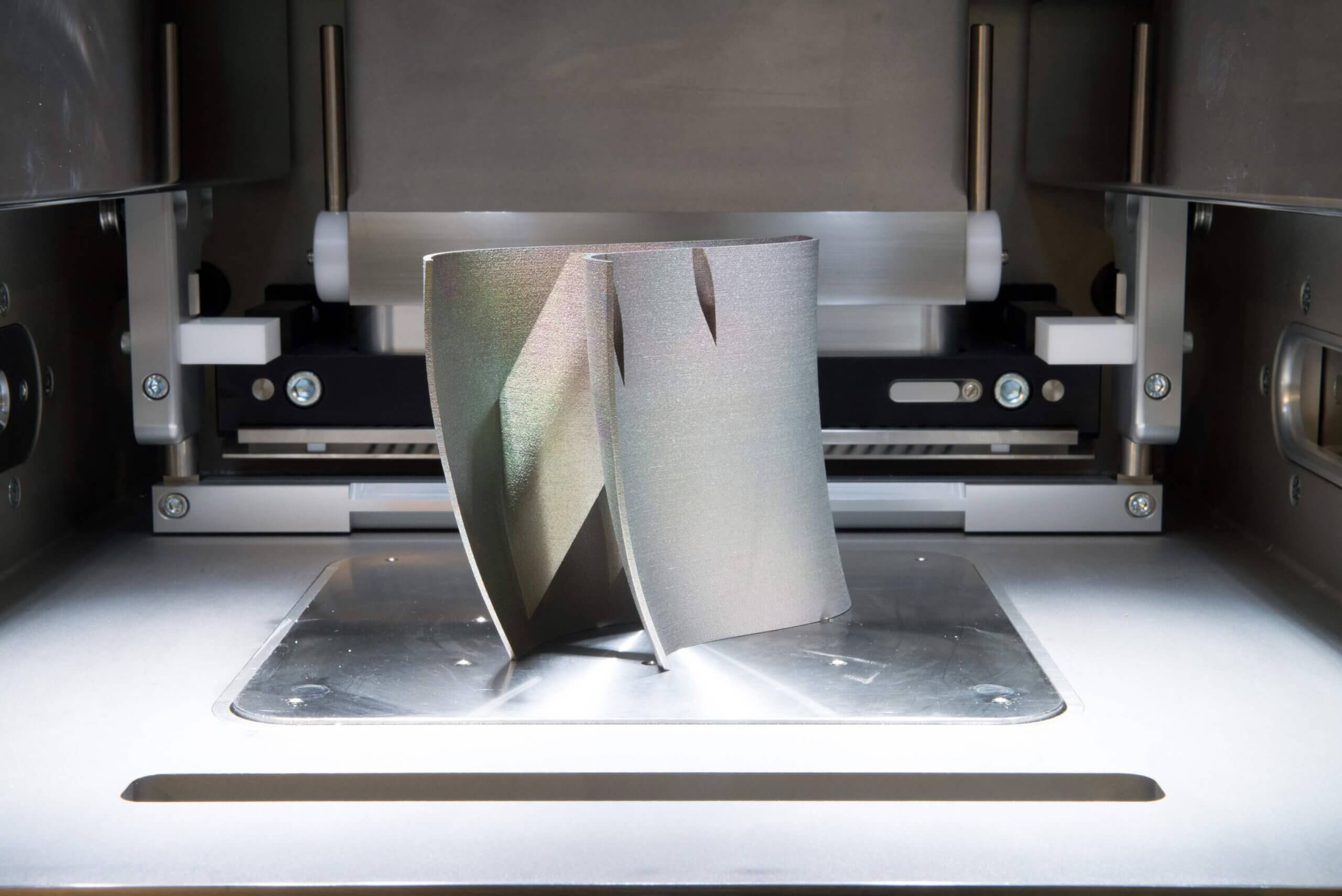

read moreOnce a 3D printed metal part is produced, the component is often far from ready to be used for its intended purpose, particularly applications in safety-critical industries with stringent quality…

read moreHistorically, the first ion implanter was helium based, constructed and operated in 1911 at Cavendish Laboratory in Cambridge by Ernest Rutherford and his students. In 1949, Shockley filed for a…

read moreThe process by which molten metal freezes in a shaped casting is a complex process. The first metal to freeze at the mold’s surface is typically fine grained and dense due to chilling…

read moreThe terms “expanded austenite” and “S-phase” were coined when first discovered in the early 1980s. The term S-phase was used to describe new peaks shown with X-ray powder diffraction (XRD)…

read moreMicrohardness vs. diffusion depth of treated stainless steel 1.4404 (316L) and hardness conversion table Kolsterising ®, proprietary to Bodycote, is a technology that greatly improves the mechanical properties of corrosion-resistant materials. Some of…

read moreGalling is a type of mechanical wear caused by a combination of friction and adhesion between sliding surfaces typically under a compressive load. It is the result of tearing and…

read moreThanks to the wide range of applications, Nitriding and Nitrocarburising processes are becoming more and more important. In addition to mechanical and technological characteristics, corrosion resistance is of vital importance…

read more