Stainless steels along with nickel based alloys are often selected for many applications in corrosive environments. While resistance to corrosion makes them a favourable choice, poor tribological behaviour may prevent a broader use of these materials. The Kolsterising® process is a proven method for the surface hardening of these materials by the diffusion of carbon. This paper intends to highlight the improvements typically seen in mechanical properties including resistance to galling, wear resistance, and cavitation erosion. Untypically, due to the nature of the process, these properties are generally improved without the usual associated reduction in corrosion resistance. Property improvements will be demonstrated using both new and existing data from Europe and North America.

If liquid or gas media and particulates come into contact with the surface of corrosion-resistant materials, there is a risk of premature wear. Additionally, it is vital for pressure containing components in valves to maintain structural integrity as this premature wear and galling can cause loss of effectiveness or failure. Many coatings and heat treatment processes have been historically used to combat these issues. A newer technology is a low-temperature surface hardening process to protect the valve components while in harsh environments.

Austenitic stainless steels

The pros and cons of austenitic stainless steels are well known and the positive aspects such as high corrosion resistance, high toughness and non-magnetic properties have been exploited for many years. However, the inherent weaknesses of low strength, low wear resistance and susceptibility to pitting, stress- and crevice-corrosion have negated their use in certain applications.

Conventional carburising

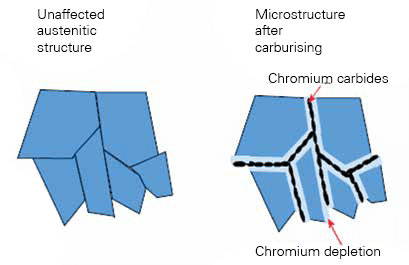

Figure 1 – Representation of chromium carbide formation after conventional carburising.

Typically, in conventional carburising or nitriding, chromium carbides or nitrides are formed at the grain boundaries due to high process temperatures (>500 ºC). This leads to chromium depletion and loss of corrosion resistance, see figure 1.

Kolsterising®

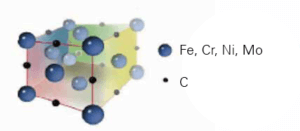

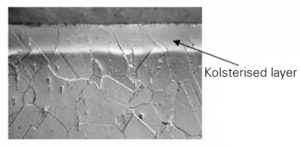

In the proprietary Kolsterising® process, carbon is diffused interstitially in the FCC matrix causing residual compressive stresses, (see figures 2 and 3). Due to the low temperatures involved, no chromium carbides are formed in the expanded austenite, often called SPhase. As a result, the surface hardness is increased substantially with no loss of corrosion resistance.

Figure 2 – Representation showing location of carbon atoms in FCC structure.

Figure 3 – Photomicrograph of AISI 316 sample showing the Kolsterised® layer.

Process details

The Kolsterising® process has never been patented so the actual parameters remain proprietary to Bodycote. Basic details however are:

- Surface hardness typically increased up to 800 to 1200 HV0.05 (equivalent to 65 to 72 HRc)

- Low temperature process (< 500ºC or < 932ºF)

- Carbon diffused into the surface in large amounts (typically 8-10 wt %)

- Diffusion layer of 10 to 40 μm (0.0004” to 0.00157”) formed in austenitic stainless steel

- Able to treat small parts in bulk as well as larger parts with individual treatment

- No changes in size due to low temperatures

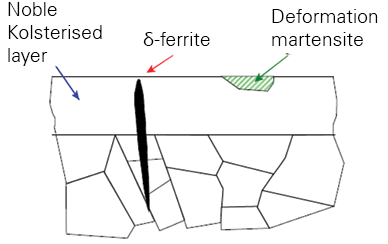

For the process to be most successful, it is necessary to remove, or at least minimize, the presence of δ-ferrite and deformation martensite, see figure 4.

Figure 4 – Influence of ferrite and martensite on corrosion resistance.

If either is present in significant amounts, corrosion resistance will be reduced. It may be necessary to remove δ-ferrite by solution annealing and deformation martensite by electropolishing prior to treatment.

Mechanical test program

New program

A test program was designed in conjunction with Bodycote’s facility in Skokie, IL. Sample material was procured from a local steel mill and was selected for availability rather than for optimal property development. Alloys used in the program were AISI 304, AISI 316 and the duplex alloy SAF 2205. The material was divided into batches, one for reference (untreated) and one for Kolsterising®. The Kolsterising® samples were vacuum solution heat treated prior to treatment.

Mechanical properties and hardness

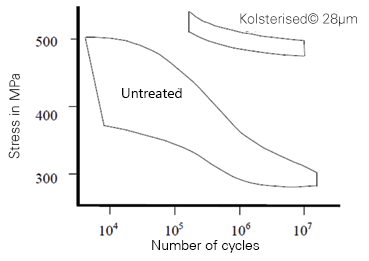

Various tests have been completed on these samples. The results displayed below are those from the more meaningful mechanical properties. Fatigue strength is typically increased by 10 to 100%, see Figure 5.

Figure 5 – Reversed bending fatigue test, AISI 316.

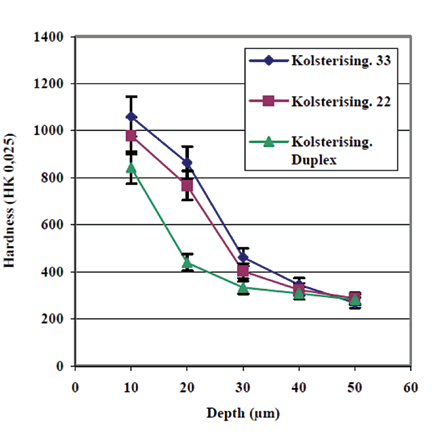

Surface hardness is of prime importance in increasing resistance to wear and galling. There are three ‘normal’ Kolsterising® treatments, 33 micron, 22 micron and duplex. The ‘33’ and ‘22’ refer to the nominal case depth in microns. A special treatment is necessary for duplex alloys, as there is a risk of embrittlement at high treatment temperatures.

Surface hardness should be measured by micro-Vickers or Knoop, using a maximum load of 50gf. See the hardness profile measurement in figure 6 for different treatment on a standardized 316L solution annealed sample.

Figure 6: Representation of hardness profiles of the three Kolsterising® treatments

Galling resistance

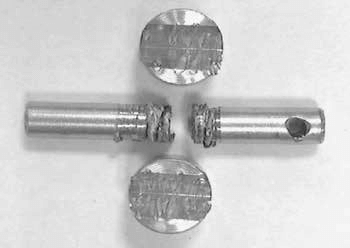

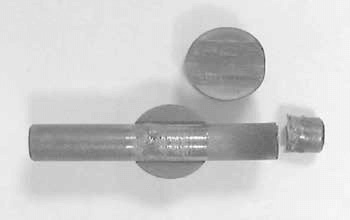

Lack of resistance to galling has been a severe failing of austenitic stainless steels and has been widely reported. A Faville Test was utilized to evaluate the galling resistance of each sample. In this test, a shaft is rotated at 330rpm while being held in a pair of jaws with a closing force of 707 N. The following photographs show the shaft and jaws after testing for three conditions: untreated (figure 7), conventional

nitriding (figure 8), and Kolsterising® (figure 9).

Figure 7 – Shaft and jaws untreated, failure occurred immediately (less than two seconds).

Figure 8 – Shaft and jaws plasma nitrided. Failure occurred after thirty-five seconds.

Figure 9 – Shaft and jaws Kolsterised®. After one minute, no failure.

Wear resistance

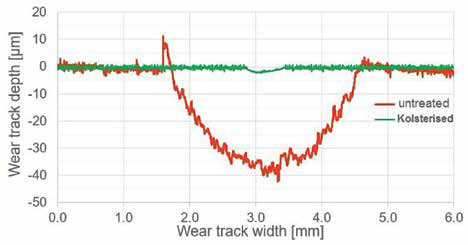

Ball-on-disc wear test. An aluminium oxide ball, Ø 5 mm, was pressed against the cylindrical surface of a rotating disc at a force of 20 N. While under pressure, the disc was rotated at a speed of approximately 50 mm/s. The rotation lasted for just over 2.5 hours giving a continuous wear track of 500 m across the disc. This was performed on untreated 316L material and 316L with Kolsterising® applied. Once testing was complete the samples were measured tactilely using a profilometer. The surface profiles of the two samples is shown in Figure 10. A high wear volume is indicated for the untreated sample, while the Kolsterised sample shows just a certain embedding at the surface.

Figure 10 – Pin-on-disc wear results for untreated and Kolsterised AISI 316L.

Summary and conclusions

For corrosive environments, austenitic and duplex stainless steels are often the first choice of designers and users. However, due to the material specific weak tribological properties and especially low wear resistance, they pose a particular challenge.

In order to enhance mechanical performance while maintaining base material ductility, coatings or hard facings can be applied. This method of improving wear can potentially be risky due to possible spalling, corrosion issues beneath the coating, or high reworking efforts that increase its total costs.

The optimal solution for a hard but still ductile surface, with no need of modifications, is Kolsterising® surface hardening. Due to the high ductility associated with very high compressive stresses, the impact of wear and galling can be greatly reduced for many applications and stainless steel materials. This is vital when dealing with pressure containing components such as valve bodies and seats, as well as other valve components like fasteners.

By examining the data from new and existing mechanical tests, it is clear that certain key mechanical properties of austenitic stainless steels and Nickel based alloys can be improved by the use of the Kolsterising® process.

- Surface hardness is increased substantially, in the range of up to 800 to 1,200 HV0.05 (equivalent to 65 to 72HRc)

- Corrosion resistant properties are maintained, if not improved (no carbide formation)

- Resistance to galling is greatly increased

- Wear properties are increased

- Cavitation erosion impacts are reduced

- Fatigue properties show a large improvement

Worthy of mention also are the facts that due to the low treatment temperature, components exhibit no change in dimensions or colour, and hardening is uniform on sharp edges, and inside bores, blind holes and gaps as little as a few microns.

This article was first published in Valve World Americas – September 2021