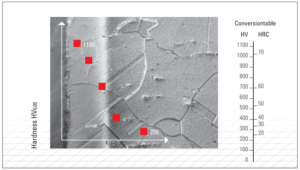

Microhardness vs. diffusion depth of treated stainless steel 1.4404

(316L) and hardness conversion table

Kolsterising ®, proprietary to Bodycote, is a technology that greatly improves the mechanical properties of corrosion-resistant materials. Some of the more commonly asked questions from our customers are answered below.

Conventional heat treatments, such as nitriding or nitrocarburizing will negatively impact the corrosion resistant properties of stainless steel alloys. Unlike conventional treatments, the Kolsterising ® process can harden the surface and maintain the corrosion resistance of these alloy systems because it is carried out at lower temperatures. During the process carbon is diffused into the surface of the part creating a super saturated solid solution commonly known as S-Phase or Expanded Austenite. Due to the low process temperatures used, the formation of chromium carbides and/or nitrides will be suppressed thereby preserving the chromium oxide passive surface layer that provides the corrosion resistance to these systems.

Properties like abrasion resistance, fatigue strength, galling and fretting threshold, and cavitation resistance are highly improved. No delamination or flaking will occur because the hardened zone is not a coating. As a reproducible and reliable solution, millions of S³P treated components are used in a broad range of industries, from the automotive sector to the offshore industry to medical technology.

What Materials can be treated with Kolsterising®?

Nearly all austenitic and duplex stainless steels, Ni-base and Co-Cr alloys.

What surface hardness can be achieved?

There can be some slight variation in hardness depending on material type, but most common austenitic (1.4404 / AISI 316L) and duplex stainless steels (1.4462 / AISI 2205), Ni-base (2.4668 / Inconel 718) and Co-Cr alloys (2.4964 / Alloy 25) can achieve > 1000 HV microhardness (conversion: ~ 70 HRC). Please ask our specialists, if your material can also be hardened.1

Is the surface brittle?

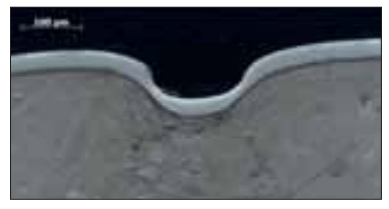

No. Because the carbon/nitrogen remains in solution in the microstructure of the diffusion zone (carbon is interstitially solved in the face centered cubic (fcc) lattice), there are no phase changes that take place. As a result, the inherent ductile properties of the austenitic base material are not altered. The process also creates a smooth transition from the hardened surface to a soft core. This further assists in maintaining the ductile behavior. Pure carbon S-Phase acts very ductile, even for rapid impact, as seen below.

Cross section of treated stainless

steel AISI 316L after rapid heavy

deformation (hammer & nail test)

Do I need to refinish the part after treatment? Are optical appearances or dimensions affected?

No, refinishing is not necessary. The low temperature diffusion of carbon does not affect the shape or size of a part, even for tight tolerances. Also there is no change in color or appearance. For a highly polished surface resulting in a mirror finish, a slight increase in surface roughness may appear. (2)

Is the corrosion resistance affected?

Due to the low treatment temperatures (below 500 °C) no chromium carbides are precipitated. Carbon is interstitially solved and the protective passive layer is uniform and dense after the treatment. (3)

Which diffusion depths can be achieved?

This depends on the material type and process chosen. It is generally a case depth of between 10 and 40 µm. (1)

What are the maximum and minimum treatable dimensions and weights?

Maximum part dimensions are Ø 480 mm x 560 mm with a maximum weight of 250 kg. There is nearly no minimum limitation to parts size and weight.

Is the whole surface area treated?

The whole surface of a part is treated, including very small holes and bores. The treatment is not line of sight dependent.

Is bulk material treatment possible?

Yes it is possible. Care has to be taken when bulk parts have flat surfaces. Point and line contacts are no problem.

Other items to note:

- Some minor variation in case depth can occur depending on the material type (chemistry) and condition (heat treatment, amount of cold work, etc.).

- The appearance of the part after the process is dependent on the delivery condition of the part.

- The passive layer (corrosion resistance) has the best properties when the microstructure of the base material is uniform. Non-uniformities such as sulfides, deformation martensite and delta ferrite may reduce the corrosion resistance.