The terms “expanded austenite” and “S-phase” were coined when first discovered in the early 1980s. The term S-phase was used to describe new peaks shown with X-ray powder diffraction (XRD) device. It was believed that a new phase was formed in the austenitic structure of stainless steels. It was later discovered this was not true and no phase change occurs in the thermochemical diffusion process; however, the name stuck and the terms “expanded austenite” or “S-phase” are today used interchangeably. At one point, “M-phase” was even used as the belief was that a martensitic structure was formed, which is also untrue.

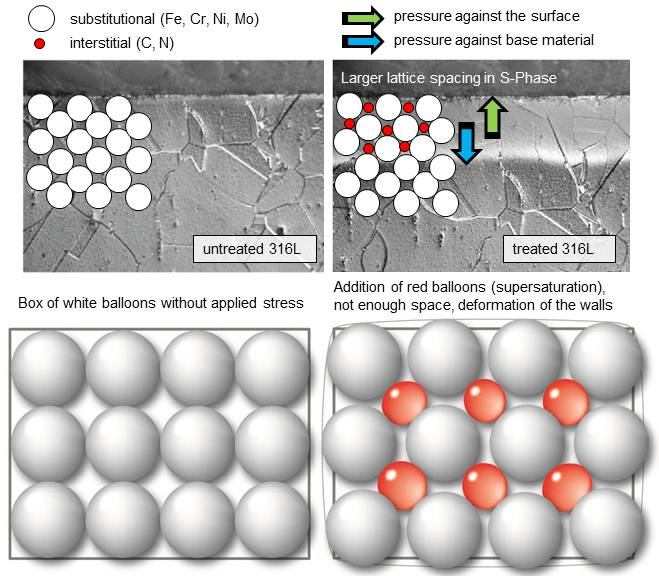

S-phase is formed by a supersaturation of carbon and/or nitrogen, up to 25 at% for the nitrogen S-phase. The implantation of the elements results are easily identifiable by a bright white layer and can be attributed to lattice expansion while the core material constrains the expansion. As a result, very high residual stresses are formed and high hardness is achieved, typically higher than 1000HV0.05. Both types of S-phase (nitrogen and carbon) are metastable with the latter, which forms in the Kolsterising® process, offering higher thermal stability and more ductility.

As demonstrated in the picture, carbon or nitrogen atoms diffuse into the interstitial spaces of the lattice and pressure is placed on the surface while the base material absorbs the expansion.

While the exact nature of Bodycote’s Specialty Stainless Steel Processes (S3P) , featuring Kolsterising® are proprietary, it can be said that these processes are environmentally safe and provides a consistent and reliable S-phase. These are two reasons why the process is often used in medical, and food and beverage applications. These low temperature processes are one of the best options for austenitic stainless and Ni-Cr alloys to apply an S-phase while maintaining the corrosion resistance of material by avoiding precipitate formation. Some benefits of applying a Kolsterised® S-phase are:

- ductility of the hardened layer

- increase in abrasion resistance

- improved fatigue life

- prevention of galling for austenitic material pairings